PRODUCTS

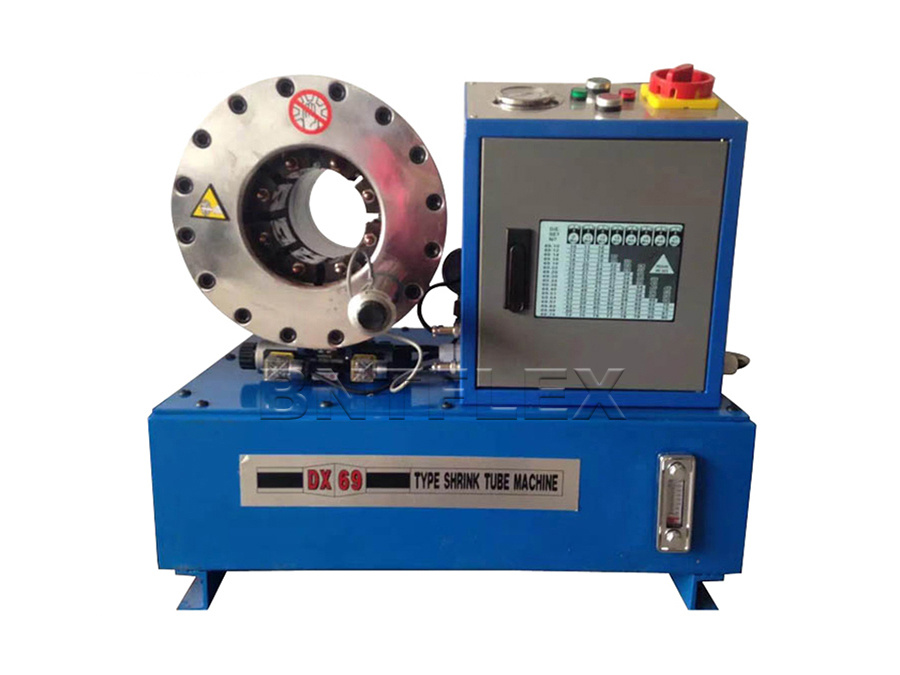

2inch-CRIMPING MACHINE

BNT81D

Workshop Crimpers

Hose Crimping Machines for the workshop - Compact, mobile and powerful

BNT81D

Application

The crimping force of the BNTFLEX BNT81D hydraulic hose crimping machine is 4200KN, with an opening diameter of 155mm, a crimp range of 4-87mm and 10 sets of standard dies. As the unrivaled classic in the 2“ field, with its narrow, innovative construction, high level of user friendliness, versatility and long service life, the machine sets the unbeatable standard for quality and cost effectiveness.

Hose capacity(max. inner diameter)

1/8" - 2" (4 wire)

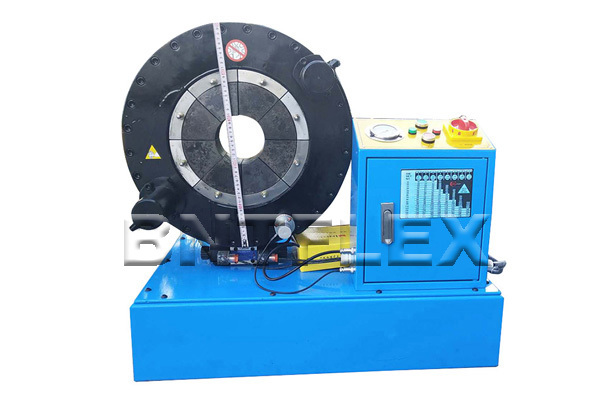

Specification

|

Model |

BNT81D |

|

Crimp force(KN/Ton) |

3800/380 |

|

Hose capacity |

1/8” - 2" (6 steel wire) |

|

Standard Die sets supplied with machine |

1/4″ – 2″, 10sets |

|

Max. Crimp range |

87mm |

|

Opening |

+60mm |

|

Opening without dies |

155m |

|

Close Speed (mm/sec.) |

6s |

|

Crimp Speed (mm/sec.) |

4.7s |

|

Open Speed (mm/sec.) |

1.5s |

|

Drive |

380V/5.5KW |

|

L x W x H Machine (mm) |

790*580*950mm |

|

Weight |

540kg |

Specification of dies

Standard dies set:

|

NO. |

Φ15 |

Φ18 |

Φ20 |

Φ23 |

Φ26 |

|

Crimp range(mm) |

15-25 |

18-28 |

20-30 |

23-33 |

26-36 |

|

Length(mm) |

65 |

65 |

65 |

65 |

65 |

|

For hose I.D(mm) |

6 |

8 |

10 |

13 |

16 |

|

NO. |

Φ29 |

Φ37 |

Φ46 |

Φ51 |

Φ63 |

|

Crimp range(mm) |

29-39 |

37-47 |

46-56 |

51-61 |

63-73 |

|

Length(mm) |

65 |

65 |

78 |

78 |

78 |

|

For hose I.D(mm) |

19 |

25 |

32 |

38 |

51 |

Details

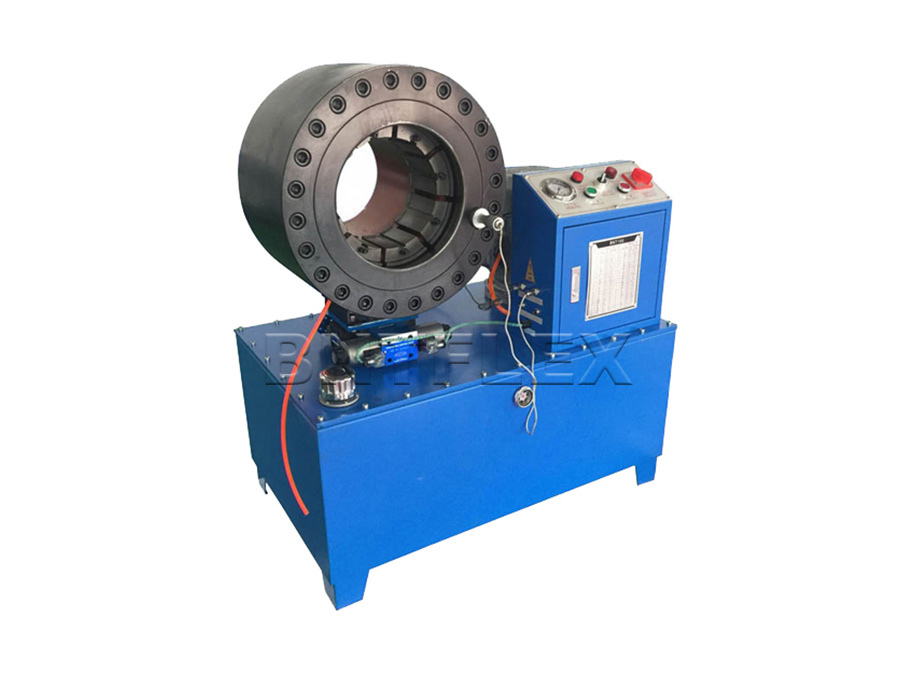

1) Material

The oil cylinder cover, oil tank and piston rod are made from 40 chromium with outstanding hardness. It is high pressure resistant with great carrying capacity and improves the durability of the oil tank and piston rod.

2) Hydraulic conduction system

With the pipeless valve block connection, the hydraulic conduction system is oil tight and durable with little heat and stable pressure conduction.

3) Die connection

Our dies are connected through magnetism, which make it convenient for assembly and disassembly, and the crimping is neat. The dies are made of Cr12 die steel.

4)Advantage

The BNT81D crimping machine is a cost-effective alternative for single-piece production.The BNT81D model(precision, durability, force and ease of use) is totally unmatched in it's own class.

Key words:

Subcategory: